Core Features

- Reel-to-reel digital knife cutting system

- Standard 2-head cutter; optional 4-head system for 50% faster production

- Precision cutting within microns using a vacuum air bed

- Slitter rewinder function with up to 5 razor knives (optional up to 8)

- Matrix waste removal system with mechanical clutch control

- Electronic eye sensor web guide for accurate tracking

- Air-expandable 76 mm unwind and rewind core chucks

- Touchscreen HMI for all settings, speed, and task control

- Dual-shaft rewinder supporting multiple core diameters

Benefits

- Delivers extremely accurate knife-cutting results, even on complex shapes

- Optional four-head station dramatically boosts productivity

- Full finishing workflow in one unit: cut, slit, count, remove waste, rewind

- Vacuum bed ensures stable, distortion-free cutting

- Ideal for short-run, variable, and on-demand digital label production

- Quick setup and operator-friendly navigation software reduce downtime

Ideal Applications

The DLD 320 is ideal for digital print shops and label producers who need fast, precise finishing without traditional die-cut tooling. It is especially well-suited for short-run and custom label jobs, variable-data designs, prototypes, and on-demand production, where knife cutting offers flexibility and zero tooling cost. The machine’s ability to handle slitting, waste removal, and rewinding makes it a strong fit for cosmetics, food and beverage, industrial, craft, retail, and promotional label applications where versatility and accuracy are essential.

Operational Advantages

The DLD 320 ensures efficient daily operation through its intuitive HMI control system, vacuum cutting bed, and automated web guiding. The air-expandable core chucks make reel loading simple, while the matrix removal and slitting assemblies operate cleanly once set, requiring no further adjustment. The optional four-head cutter station significantly enhances processing speed, and the dual-shaft rewinder offers flexibility for various core diameters. Together, these features create a robust and dependable finishing workflow that minimizes operator effort while delivering consistently high-quality results.

System Specifications

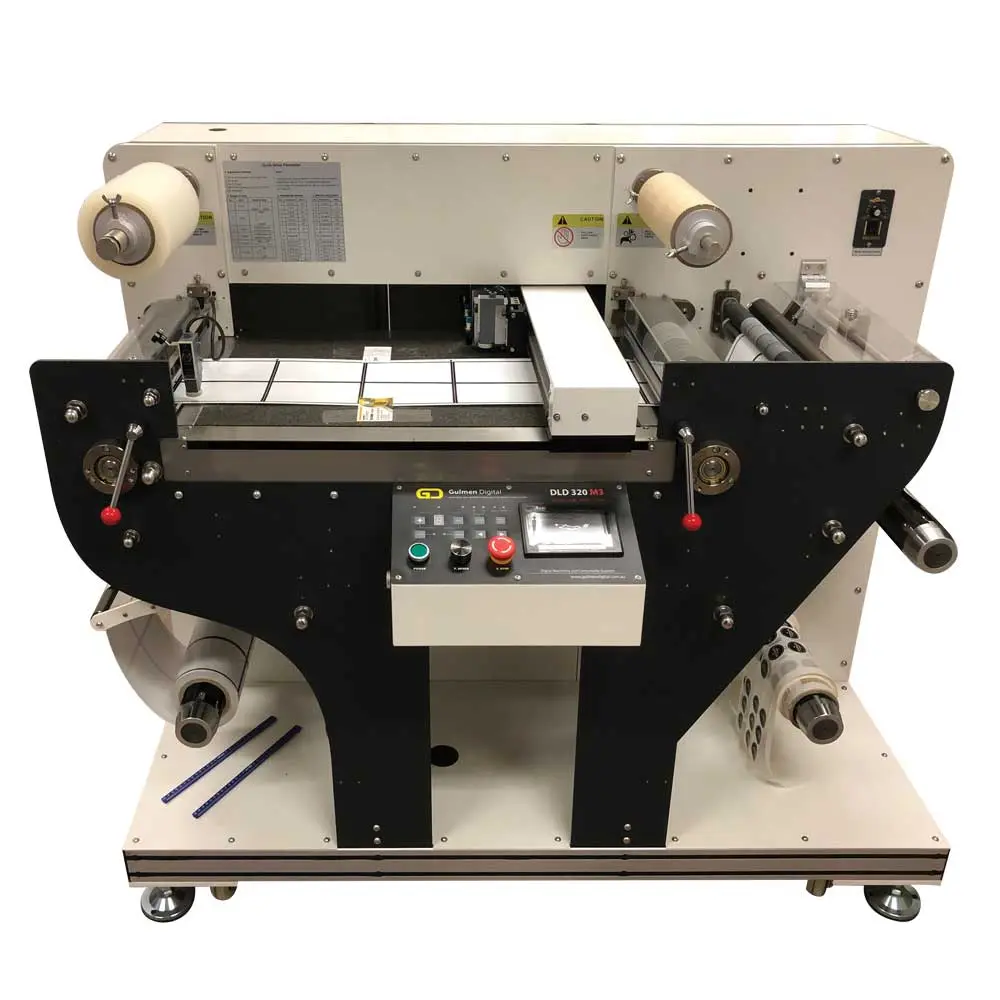

Manufacturer | Gulmen Digital |

Model | DLD 320 Digital Knife Label Cutter |

Cutting Heads | 2 (optional 4) |

Maximum Cutting Speed | 6 m/min |

Vacuum Cutting Bed | Yes (for micron-level accuracy) |

Matrix Waste Rewinder | Yes |

Slitting Knives | 5 standard (optional up to 8) |

Web Guide System | Electronic eye sensor |

Unwind Core Chuck | 76 mm air-expandable |

Rewind Core Diameters | 76 mm (optional 25.4, 38, 40, 50 mm) |

Tension Control | Electronic tension control |

Laminate Station | Yes, with lateral adjustment |

Operation Panel | Touchscreen HMI |

Cutting Method | Plotter knife, digital control |

Functionality | Cut, slit, waste removal, count, rewind |