Industrial-grade speed, accuracy, and traceability—built for production lines

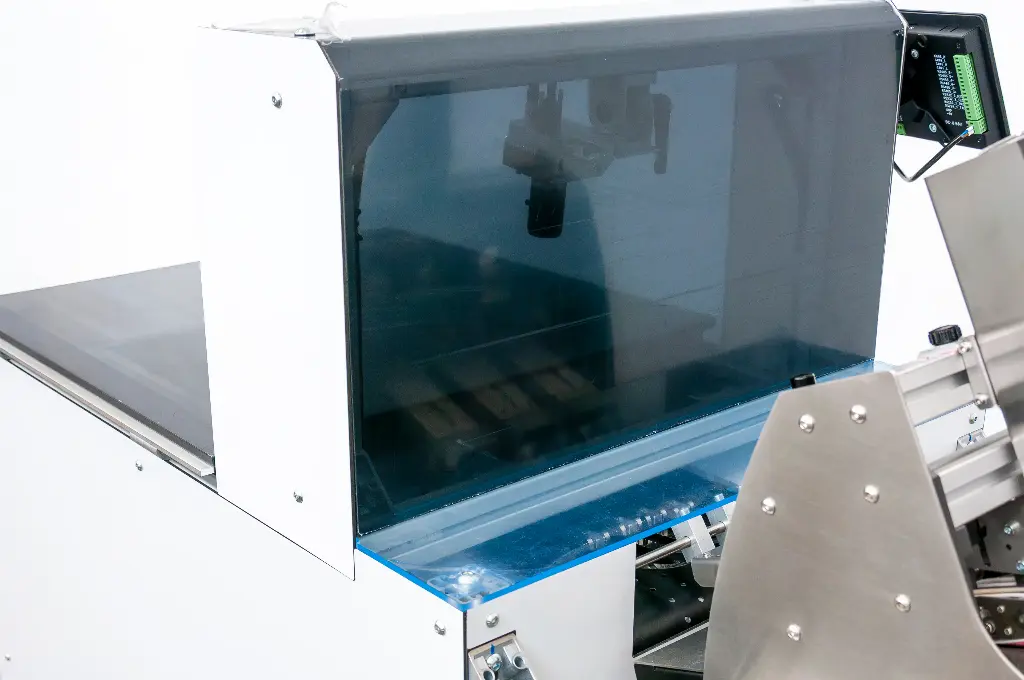

Get flawless, high-volume document capture without bottlenecks. The High-Speed Industrial Scanner combines a 2K grayscale line camera, intelligent PC control, and production-safe I/O to deliver fast, reliable, and fully traceable image acquisition. From print shops to regulated industries, it seamlessly integrates into your workflow, scales with demand, and keeps teams moving.

Primary keywords: high-speed sheetfed scanner, industrial document scanner, production line scanner, 2K line scan camera, CSV/XML logging, SHA-512 file hash, I/O integration

Secondary keywords: enterprise scanning solution, QA traceability, logistics scanning, prepress scanning, automated file structuring

Why it wins (at a glance)

- Speed & uptime: Engineered for continuous operation and rapid throughput.

- Audit-ready data: Automatic CSV/XML logs + SHA-512 file hash for integrity.

- Seamless integration: Network-based storage, modular I/O for diverter and automations.

- Operator-friendly: Start/Stop, Emergency Stop, Job Selector, and a simple LCD counter.

- Lifecycle cupport: Technician and operator training, remote help (9:00–17:00), on-site options.

Designed for your environment

Printing & Prepress (Printshops, Packaging & Labels)

Digitise customer originals, proofs, and assets fast. Reduce manual handling, accelerate prepress, and complete jobs more quickly.

Regulated Sectors (Banking, Healthcare, Legal/Gov)

Meet compliance and audit needs with structured logs, file hashing, and clean data hand-offs to DMS/EMR/ECM.

Manufacturing & Engineering

Capture and archive QA reports, certifications, and drawings with traceability that meet ISO and safety audit standards.

Key Benefits

- High productivity, low downtime

Industrial components + automated workflows keep lines moving and operators focused on value-add work. - End-to-end traceability

Every image is paired with metadata (job type, folder, filename, timestamp, SHA-512) to support audits and version control. - Fewer errors, less rework

Simple controls, a clear LCD counter, and automated file structuring reduce manual steps and misfiles. - Future-proof integration

I/O outputs for eject units and a network-first data model make expansion and system upgrades straightforward. - Confidence from day one

Technician training (1–2 days) and operator training (4 hours) ensure smooth adoption and consistent results.

Features that matter

Comprehensive Control Interface

- Start/Stop, Emergency Stop, and Job Selector

- LCD counter with manual reset

- I/O outputs for eject units and later add-ons

Outcome: fast onboarding, safer operation, and fewer production mistakes.

Advanced Line Camera System

- Up to 2K resolution grayscale line camera

- Crisp, detail-rich captures for QA, archiving, and prepress

Outcome: consistent, high-quality images—no more unusable scans.

Intelligent PC Control & Data Management

- Industrial PC orchestrates scanning and control

- Auto-save image packages to network drives

- Auto-generated CSV or XML logs with: Job Type, Folder, Filename, Timestamp, SHA-512 file hash

Outcome: audit-ready records and secure, verifiable archives.

Automated File Structuring

- Each run is saved in its own folder

- Automatic job closure: data file is finalised by changing extension to .start

Outcome: clean, tamper-resistant structure that teams can trust and retrieve quickly.

Training & Support

- Technician Training: 1–2 days pre-delivery (preventive maintenance)

- Operator Training: 4 hours on-site post-install

- Support: Remote (9:00–17:00) + optional on-site assistance

Outcome: maximum uptime, faster resolution, and self-sufficient teams.

Differentiators vs. Office-grade Scanners

Capability | Typical Office Scanners | High-Speed Sheetfed Scanner |

Logging & Integrity | Basic exports | CSV/XML + SHA-512 validation |

Imaging | Low/standard resolution | 2K grayscale line camera |

Integration | Fixed, limited I/O | Modular I/O + network storage |

Usability | Complex or consumer-oriented | Industrial controls + LCD counter |

Support | Basic warranty | Training + remote/on-site support |

Tech Highlights

- Camera: Up to 2K grayscale line camera

- Controls: Start/Stop, Emergency Stop, Job Selector

- Interface: LCD display with manual counter reset

- Integration: I/O outputs for eject units & automation

- Data management: Network drive saving; CSV/XML logs

- Security/Integrity: SHA-512 file hash per image file

- Session handling: Per-run folders; auto-finalization via .start

- Support window: Weekdays 09:00–17:00 (remote); on-site by request

- Training: Technician (1–2 days), Operator (4 hours)

Pricing & Deployment

- Value-based packages with options for extended warranty and service bundles

- Enterprise rollouts with multi-site training and performance SLAs

- Integration services for DMS/ECM/EMR and automation (on request)

Frequently Asked Questions

Is it compatible with our DMS/ECM or EMR?

Yes. Images are stored on network drives and accompanied by CSV/XML logs, simplifying ingestion and indexing.

Can we add diverter units or automation later?

Yes. The system includes I/O outputs for current control and future expansion.

How do you guarantee data integrity?

Each image has a SHA-512 file hash stored alongside its metadata for verification and auditing purposes.

What onboarding is included?

Technician training (1–2 days) before delivery and on-site operator training (4 hours) after installation.

Do you provide remote support?

Yes—9:00–17:00 on workdays, with optional on-site support for troubleshooting and optimisation.