Core Features

- High-Speed, High-Quality Printing

- 1600 × 1600 dpi resolution with durable aqueous pigment inks for sharp, vivid results.

- Integrated Laser Finishing

- The 250W laser engine performs full-cut, half-cut, perforation, marking, and scribing — all in one pass.

- ANY-FLOW Intelligent Workflow

- All-in-one RIP and job management software with VDP (Variable Data Printing) and CMS (Color Management System).

- Auto Job Changeover

- Enables seamless, unattended switching between jobs in just minutes.

- Built-in Lamination and Slitting

- Inline cold lamination and up to 7-knife slitting modules for a complete print-to-finish workflow.

- Smart Automation (AIMS)

- Automatically manages file sorting, layout optimization, and mark placement to minimize setup time.

Benefits

- Fast Turnaround – Set up in just 5 minutes, with no need for analog plates or dies.

- Cost Efficiency – Eliminate tooling and downtime costs; reduce labor with automated workflow.

- Easy Operation – Intuitive interface; full training can be completed in just 3 days.

- Continuous Production – No manual transfer or secondary setup required.

- Scalable Output – Ideal for short-run to mid-volume jobs demanding customization and flexibility.

Ideal Applications

Label Applications

- Food & Beverage

- Cosmetics & Beauty

- Chemicals & Pharmaceuticals

- Textiles & Electronics

Packaging Applications

- Snacks & Pet Food

- Supplements & Organic Products

- Coffee, Tea, and Liquid Packaging

Operational Advantages

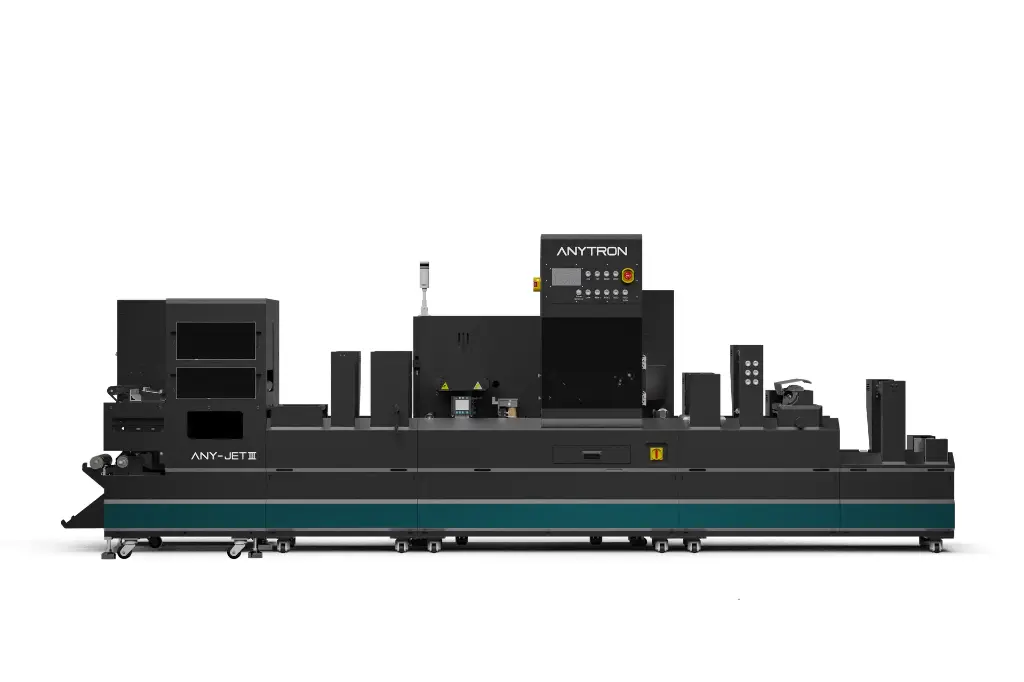

Built for efficiency and flexibility, the ANY-JET III integrates every process — from printing to cutting — into one continuous, fully automated workflow.

Its single-operator design allows smooth management of multiple jobs, while automatic registration and mark detection systems drastically reduce errors and waste. The compact footprint and single-phase 220 V power requirement make it ideal for modern production environments where space and energy efficiency matter.

Seamless software integration with ANY-FLOW ensures easy connectivity to prepress and print management systems, guaranteeing stable performance, accurate color control, and simplified job tracking from start to finish.

Technical Specifications

Manufacturer | ANYTRON by BITEK TECHNOLOGY |

Maximum Media Width | 324 mm (12.75”) |

Print Engine | High-Durability Pigmented Aqueous Inkjet |

Ink Type | CMYK – 10 L per color |

Print Resolution | 1600 × 1600 dpi |

Cutting Area | 300 mm width × unlimited length – split cut |

Cutting Mode | Full-cut, half-cut, perforation, marking, scribing |

Laser Power | 250 W |

Maximum Web Speed | 45 m/min |

Maximum Roll Diameter | 700 mm |

Laminator | Built-in (cold lamination with release liner) |

Slitter | Built-in (up to 7 knives) |

Second Rewinder | Built-in |

Power | Single Phase 220 V |

Software | ANY-FLOW, AIMS |

Options | Auto job changeover, pneumatic lift |

Dimensions (W × H × D) | 4616 × 1885 × 1215 mm |