Key Functionalities & Benefits

- Complete mechanical & electrical design – Tailored cell construction for optimal workflow and easy maintenance.

- Vacuum label applicator – High-precision label pick-up and placement with gentle handling for sensitive drives.

- PLC & robot control integration – Coordinated control logic ensures synchronised motion and consistent throughput.

- Vision system implementation – Cameras identify drive orientation and verify correct label placement in real time.

- Automatic product identification – Reads product data and assigns corresponding tracking labels.

- Error detection & correction – Vision feedback automatically rejects or repositions misapplied labels.

- High-speed operation – Optimized motion sequences minimize cycle times while maintaining accuracy.

- Traceability-ready – Enables complete product tracking for audit and quality control.

- Low maintenance design – Simplified service access and robust components for 24/7 operation.

- Scalable architecture – Easily adaptable for other product sizes, shapes, or labelling requirements.

Cross-Industry Opportunities

Although developed for data storage manufacturing, the Robot Labelling Cell’s modular design and automation logic can be applied across numerous industries:

- Electronics manufacturing – precise component identification and serial labelling

- Automotive production – part traceability and compliance labelling

- Medical devices – sterile, accurate label application under quality control standards

- Packaging & logistics – automated barcode or tracking label application

- Consumer goods – consistent branding and batch tracking

This flexibility makes it ideal for any production environment that values accuracy, efficiency, and traceability.

Take precision labelling to the next level with automation that guarantees accuracy and traceability.

Let’s design a robotic labelling cell that adapts to your products and scales with your production.

Technical Scope

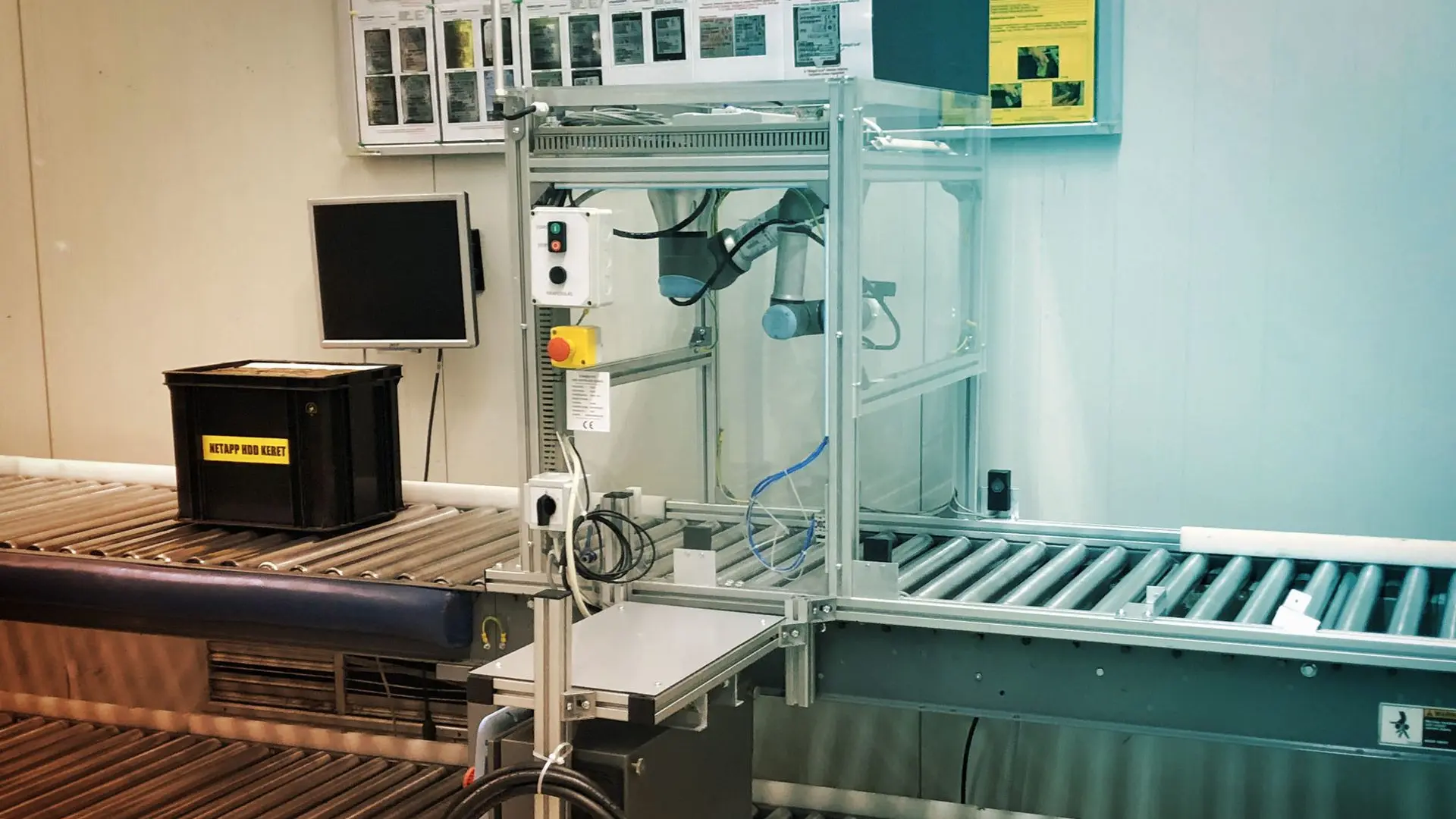

- Robot type: 6-axis industrial robot

- Labelling system: Vacuum-based label pick & place applicator

- Control system: PLC-based with integrated robot coordination

- Vision system: Position detection and label verification cameras

- Software: Custom PLC and robot code for motion and process control

- Connectivity: Production database integration for product tracking

- Safety: Guarded cell with interlocks and emergency stops

- Design scope: Full mechanical, electrical, pneumatic, and software engineering

Results / Impact

- Increased labelling precision and repeatability, eliminating manual alignment errors.

- Reduced cycle times, boosting line throughput and consistency.

- Improved traceability and compliance are essential for serialised production environments.

- Lower operational costs, thanks to automation-driven efficiency and reliability.

Competitive Differentiators

- Complete turnkey automation — from design to commissioning.

- Integration of robotics, PLC control, and vision in one cohesive system.

- High precision vacuum label applicator, engineered in-house.

- Adaptable cell architecture, ready for future product or process changes.

See more