Key Functionalities & Benefits

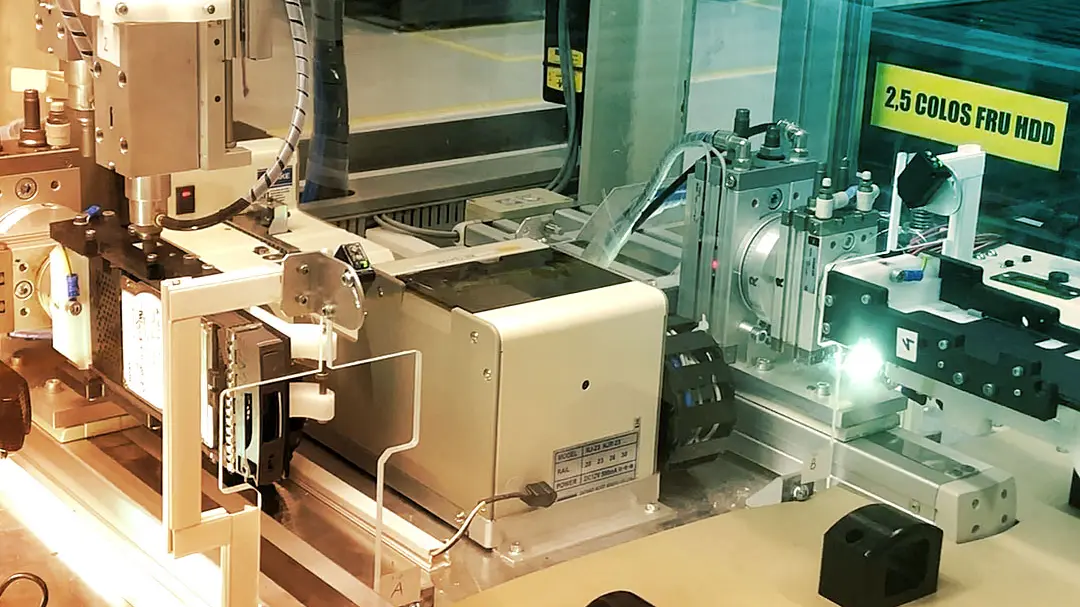

- Complete mechanical & electrical design – Custom frame and layout engineered for maximum accessibility and serviceability.

- Pneumatic system integration – Fast, reliable clamping and fastening operations with precise air control.

- PLC-based process control – Ensures synchronised motion and tool coordination for flawless cycle execution.

- Robot control software – Smart motion programming optimises pick-and-place speed and torque application.

- Vision system implementation – Integrated camera guidance verifies position and alignment for zero-error fastening.

- Production tracking system – Captures cycle data, quality metrics, and component traceability for full process visibility.

- User-friendly interface – Intuitive operator panel simplifies setup, monitoring, and maintenance tasks.

- High precision & repeatability – Micron-level positioning accuracy improves assembly quality and reduces rework.

- Compact footprint – Optimised cell layout fits seamlessly into existing production lines.

- Reliable, low-maintenance operation – Designed for continuous 24/7 performance with minimal downtime.

Cross-Industry Opportunities

While developed for data storage server assembly, this automation cell concept can be adapted across several industrial sectors:

- Electronics manufacturing – automated PCB or device sub-assembly

- Automotive – component fastening, sensor installation, or small-part assembly

- Medical device production – precision assembly under strict quality standards

- Packaging & logistics – robotic sorting and fixture handling

- Industrial equipment manufacturing – repeatable multi-step assembly processes

The modular design allows quick customisation for new product geometries, fastening tools, or quality inspection requirements.

Automate your assembly line with precision robotics and real-time traceability.

Partner with Door2World to design and build a custom robot cell that delivers consistency, safety, and performance 24/7.

Technical Scope

- Robot type: 6-axis industrial robot

- Control system: PLC-based with integrated HMI

- Pneumatics: Actuators and custom vacuum tools with valve controlled network

- Vision: Camera-based part detection and alignment verification

- Software: Custom PLC and robot program integration, production tracking database

- Safety: Light curtains, emergency stop circuits, and interlocked doors

- Connectivity: Data logging and MES/ERP integration ready

Results / Impact

- Fully automated fastening reduced manual labour and human error.

- Cycle time reduction increased throughput and production consistency.

- Traceable production data enhanced quality assurance and compliance.

- Reliable 24/7 operation minimised maintenance interruptions.

Competitive Differentiators

- Complete in-house development — from concept to commissioning.

- Integration of robotics, vision, and PLC controls into one cohesive system.

- High-precision fastening with live production tracking is uncommon in standard robotic assembly cells.

- Proven adaptability for different products and industries.