Key Functionalities & Benefits

- Intuitive user interface – Touch-optimised, operator-friendly design built for simplicity and productivity.

- Real-time monitoring – Displays live machine status, production counters, and performance indicators.

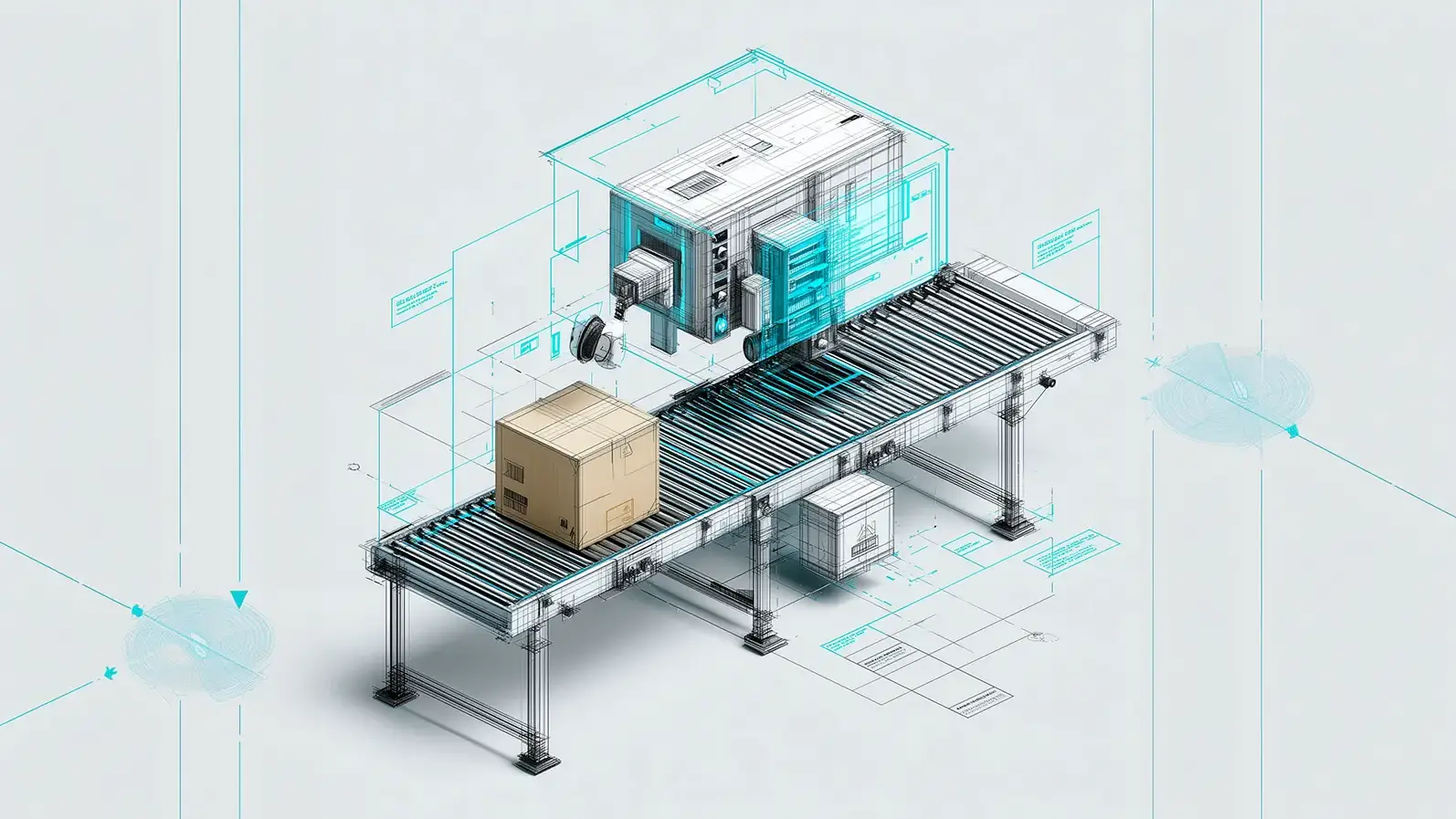

- Full system integration – Centralized hub controlling print engine, conveyor, and vision systems.

- Computer vision module – Processes live image data for print validation and envelope tracking.

- Read–print–verify workflow – Manages data flow between barcode reading, printing, and verification in real time.

- Multi-camera operation – Supports various configurations for different inspection and tracking modes.

- Modular architecture – Easily extendable for new hardware, sensors, or production features.

- High reliability – Designed for 24/7 industrial operation with automated fault detection.

- User roles & access control – Customizable permissions for operators, supervisors, and maintenance staff.

- Data logging & reporting – Generates production and verification reports for audit and traceability.

Cross-Industry Opportunities

Although developed for industrial printing and envelope production, this controller and vision software framework can be adapted to numerous automation fields, including:

- Packaging and labelling – print verification, barcode tracking, and defect detection.

- Electronics manufacturing – visual inspection and assembly verification.

- Automotive components – surface inspection and production data management.

- Pharmaceutical production – packaging validation and serialisation.

- Food & beverage lines – quality assurance and real-time process control.

The scalable, modular architecture makes it ideal for any industry requiring real-time machine control and visual inspection integration.

Looking to make your machines smarter and easier to control?

Our custom-built controller and vision software deliver real-time data, intuitive interfaces, and precision automation for industrial performance.

Technical Scope

- User interface: Custom-designed, touch-enabled UI with real-time data visualisation.

- Software core: Central control system for synchronised operation of all machine components.

- Vision system: Real-time image processing for Read–Print–Verify operation.

- Camera support: Multi-camera configuration for pre- and post-process inspection.

- Communication protocols: Integration with PLC, print engines, and production tracking databases.

- Data handling: Live data exchange, job management, and production reports.

- Platform: Embedded Windows- or Linux based industrial PC environment.

Results / Impact

- Increased production reliability through real-time data and automated fault alerts.

- Simplified operator workflow with an intuitive, visually guided interface.

- Improved quality control via integrated vision inspection and validation.

- Reduced downtime and waste through automated error detection and recovery.

Competitive Differentiators

- Developed entirely in-house — UI, controller logic, and vision software, all custom-built.

- Seamless Read–print–verify workflow integration with industrial printing systems.

- Modular vision system adaptable to multiple camera configurations.

- Operator-first UI design — intuitive, touch-optimized, and process-driven.